Precision Engineered. Rigorously Tested. Built to Last

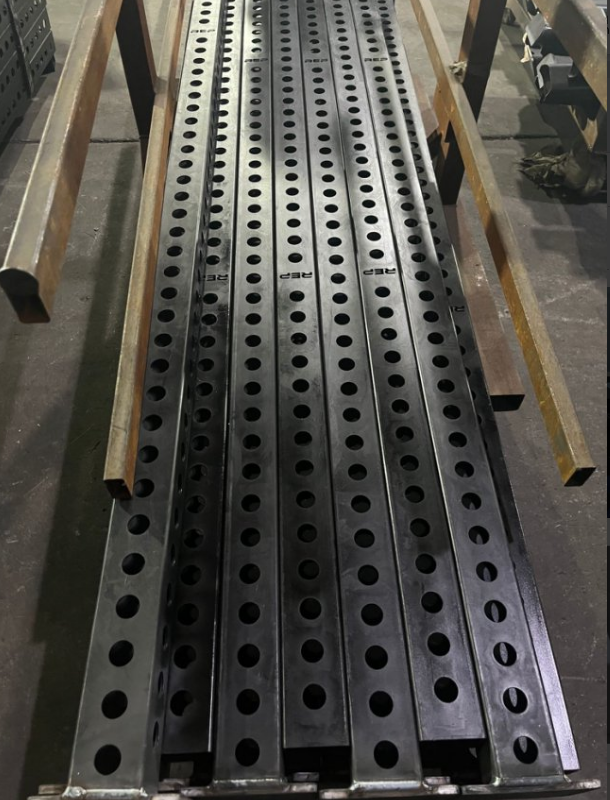

Material Selection & Durability Testing- Steel Products

Steel Fitness Equipment(Rigs&Racks,Weight Benches, Fuctional Trianer, Steel Plates, leg press machine, chest machine, lat pull down etc.): High-grade ASTM A36/1045 steel, tested for tensile strength (≥500 MPa) and corrosion resistance (salt spray tested for 500+ hours).

Spectrometer Testing Machine

Guaranteeing Material Integrity.

Prevents substandard steel from entering production.

Salt Spray Testing Machine

500+ hours of 5% NaCl spray exposure to Verifiy protective coatings (powder/paint) withstand harsh conditions.

Ensures gym equipment functional after salt fog exposure

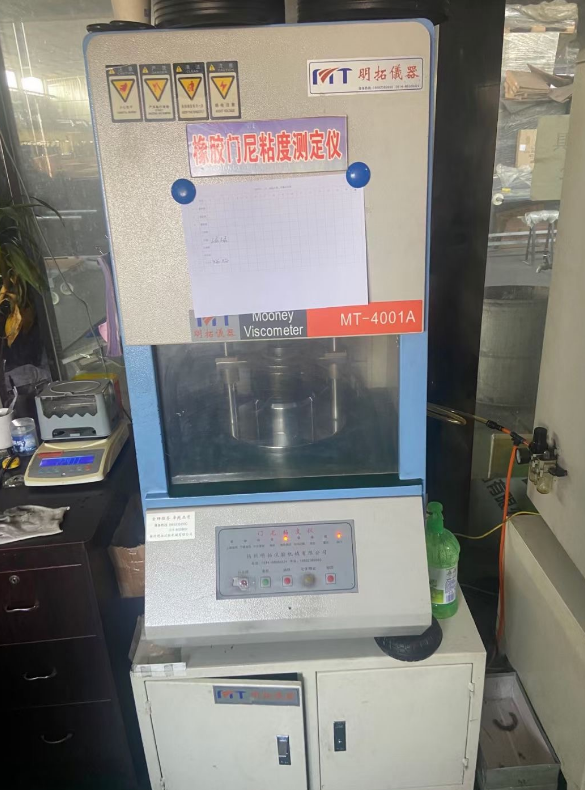

Material Selection & Durability Testing- Rubber Products

Rubber Products(dumbbells, bumper plates, rubber flooring, resistance bands, etc.)

Eco-friendly virgin rubber (Shore A hardness 70-95, abrasion resistance ≤90mm³ per DIN 53516).

Rubber Microcomputer Tensile Testing Machine for Mechanical Property Testing

(1)Tensile Strength Test: Measures maximum pull force before rubber breakage (e.g., verifying bumper plate rubber’s anti-tear capability under high impact)

(2)Tear Resistance Test: Simulates edge cracking resistance when bumper plates are dropped (compliant with ASTM D624 standard)

(3)Elongation Test: Validates rubber’s stretchability (ensures flooring rebounds after compression without permanent deformation)

(4)Fatigue Resistance Test: Repeated stretching to simulate long-term aging (e.g., for functional training equipment components)

Applications:

Bumper plate rubber edges must pass ≥15MPa tensile strength test to prevent cracking during weightlifting

Rubber flooring requires 500+ stretch cycles to guarantee deformation resistance under prolonged use